In the realm of visual communication, printing techniques play a crucial role in bringing ideas to life. From ancient forms of printmaking to cutting-edge digital technologies, the world of print offers an incredibly diverse range of methods to create captivating and impactful visuals. Whether you are a designer, artist, or simply curious about the world of printing, this article will explore some of the most fascinating techniques and their unique characteristics. Join us on this journey as we delve into the art of printing.

Introduction: Unveiling the Power of Print

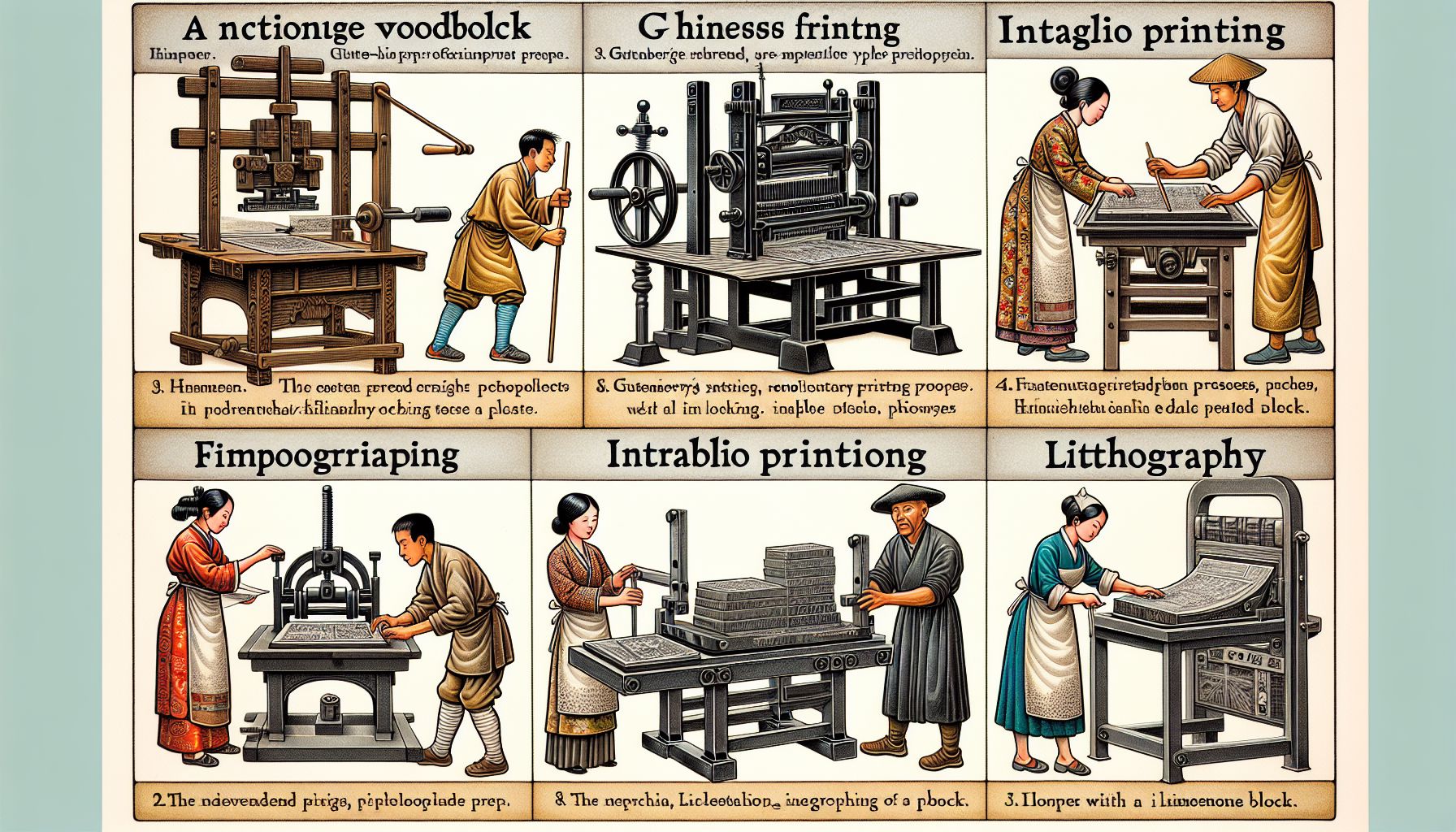

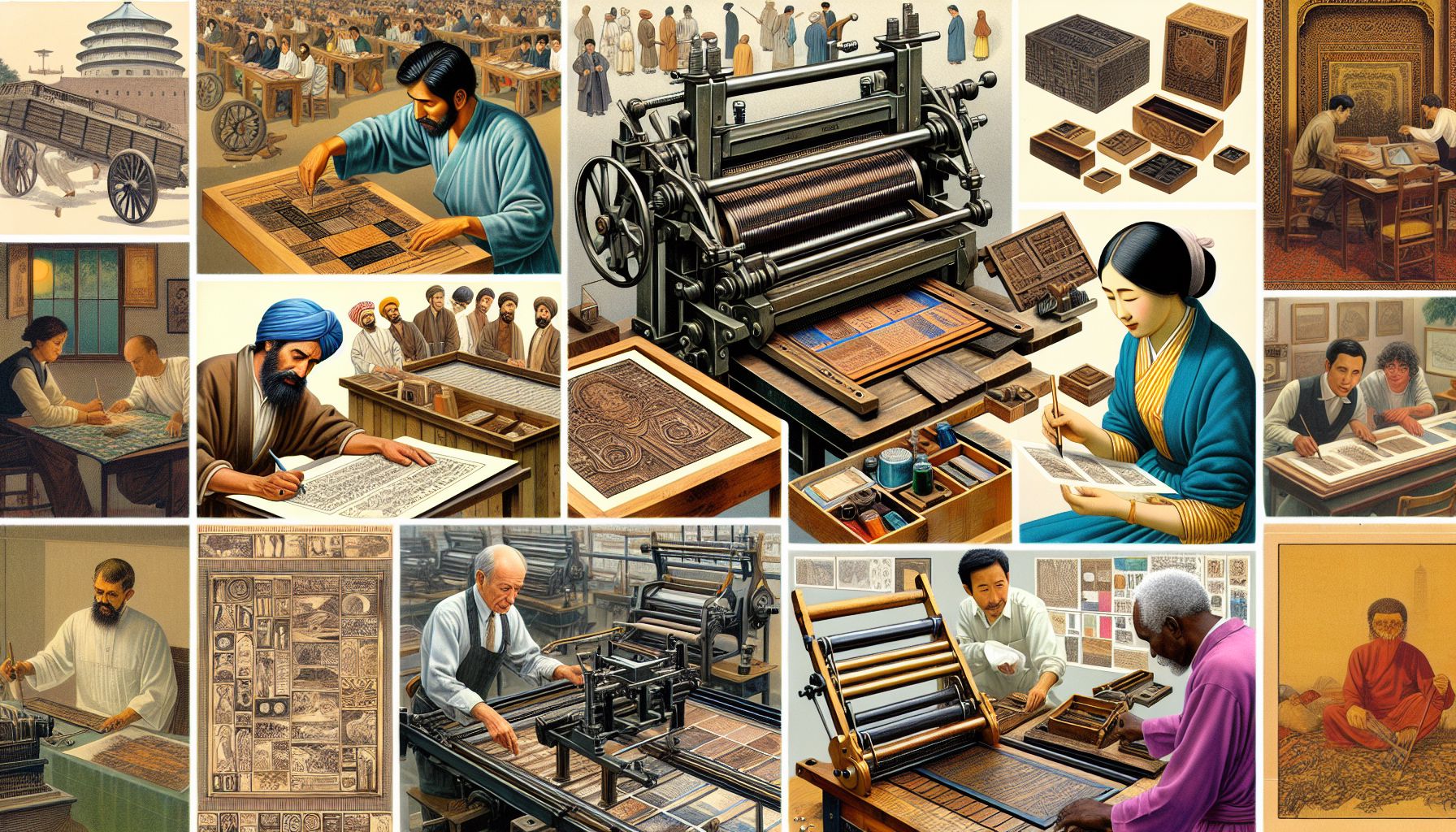

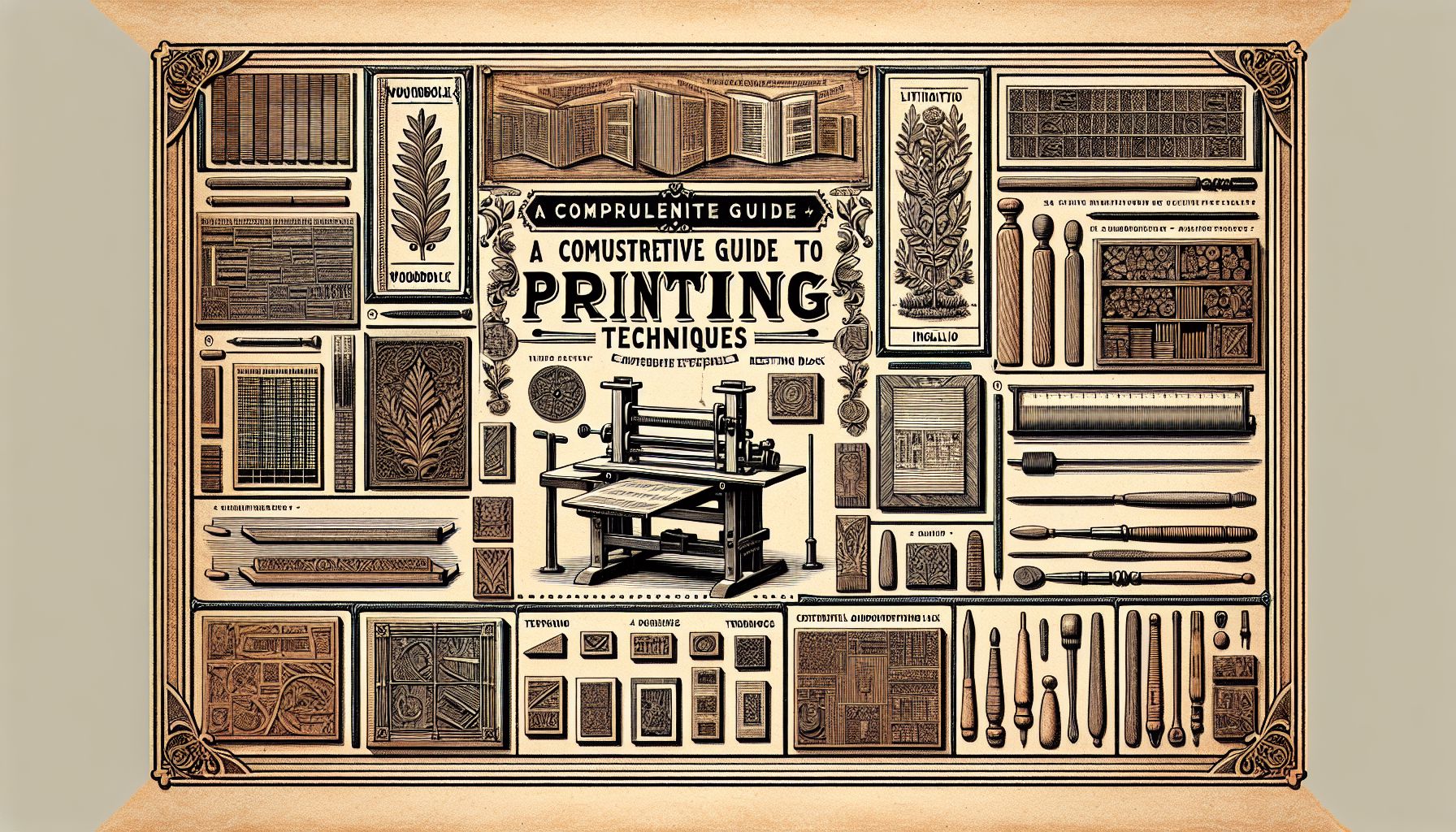

Print has been a fundamental medium for sharing information and artistic expression since ancient times. From the Chinese invention of woodblock printing in the 9th century to Johannes Gutenberg’s revolutionary moveable type printing press in the 15th century, humanity has continuously developed innovative techniques to capture and share ideas.

Printed materials are all around us, shaping our lives in countless ways. From books that transport us to distant lands, to eye-catching advertisements that make us stop and ponder, the power of print is undeniable. Understanding the unique characteristics of various printing techniques can greatly enhance one’s ability to create captivating visuals and effectively communicate messages.

The Art of Print: Techniques and Applications

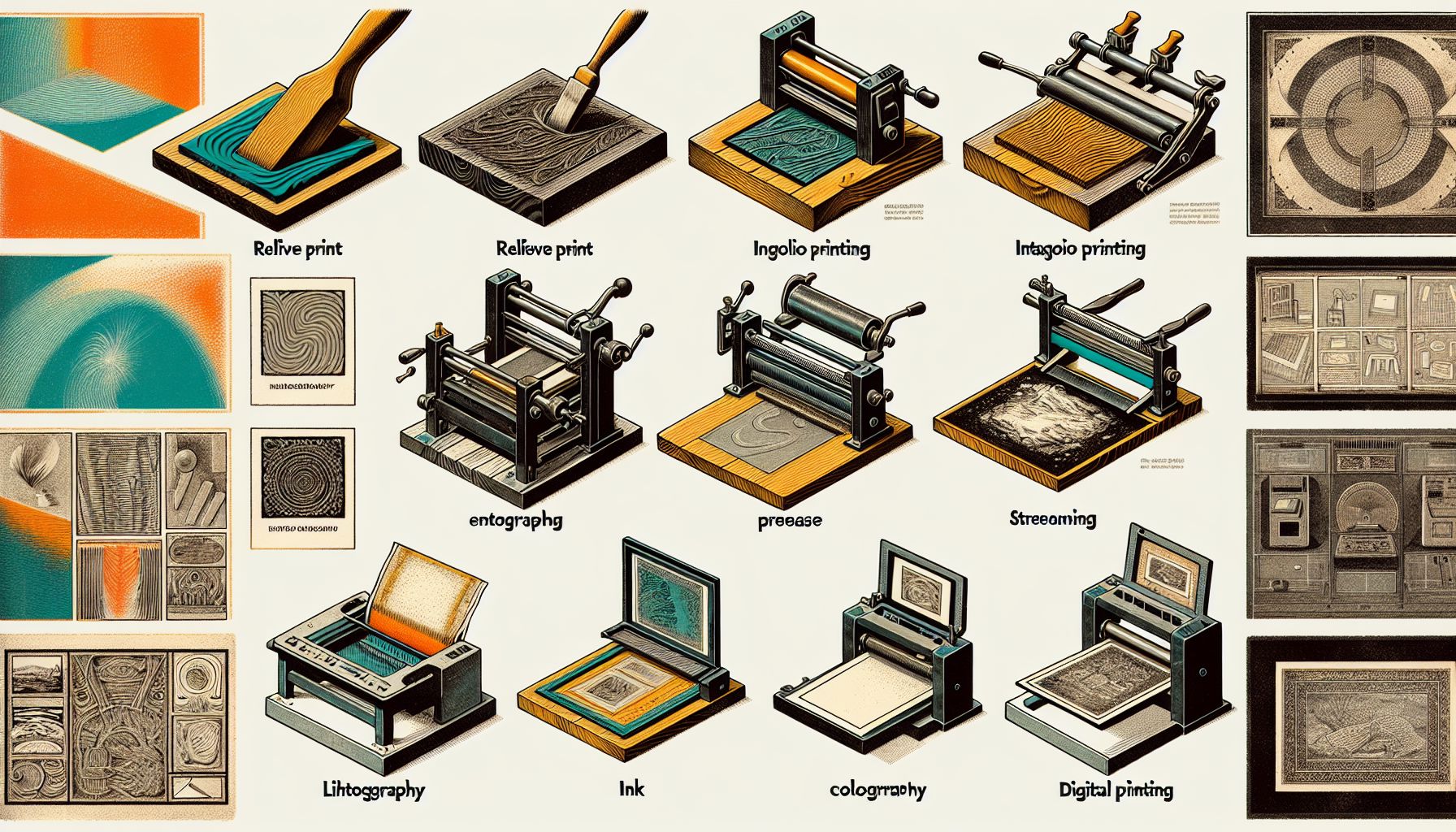

1. Relief Printing

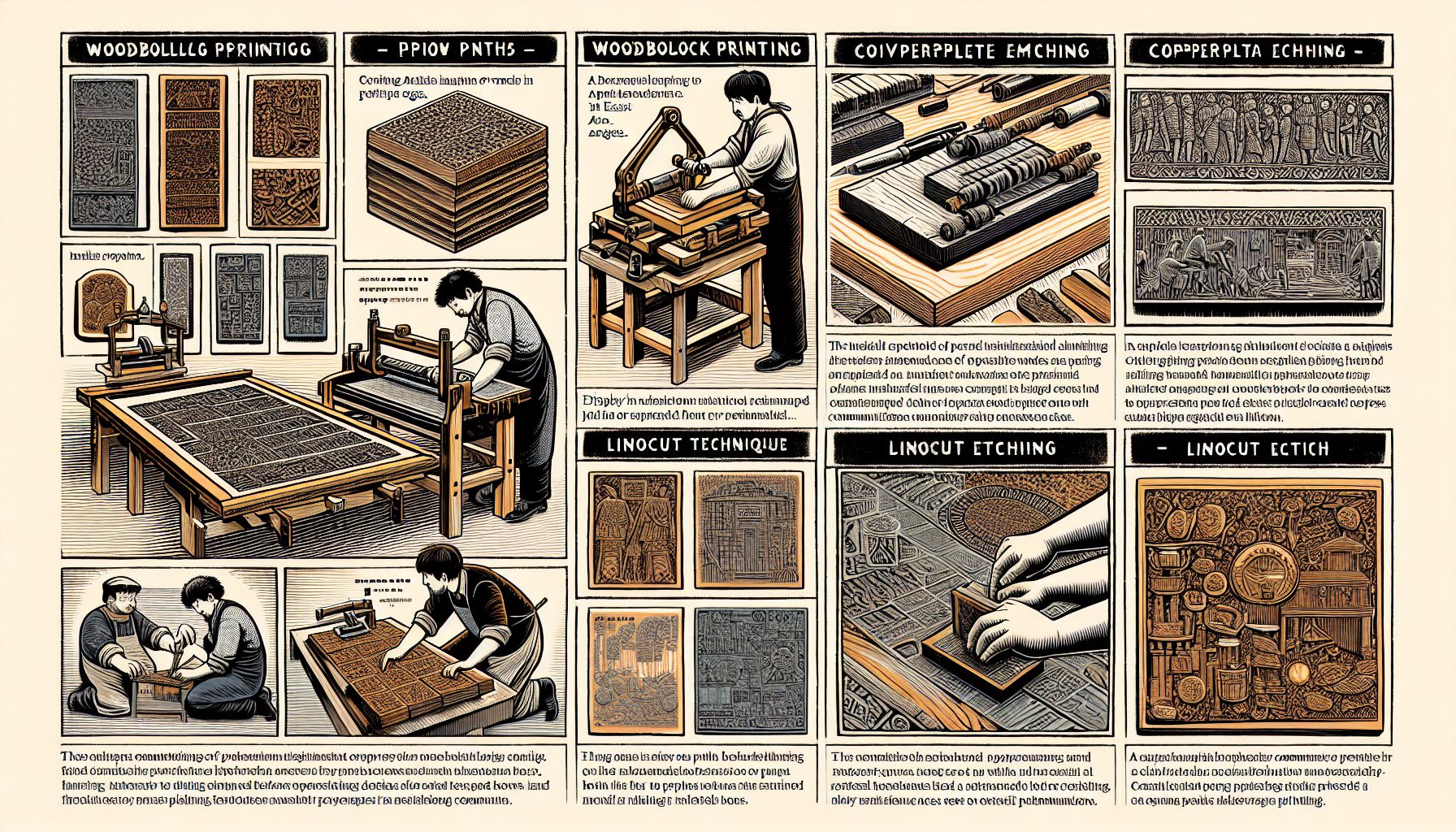

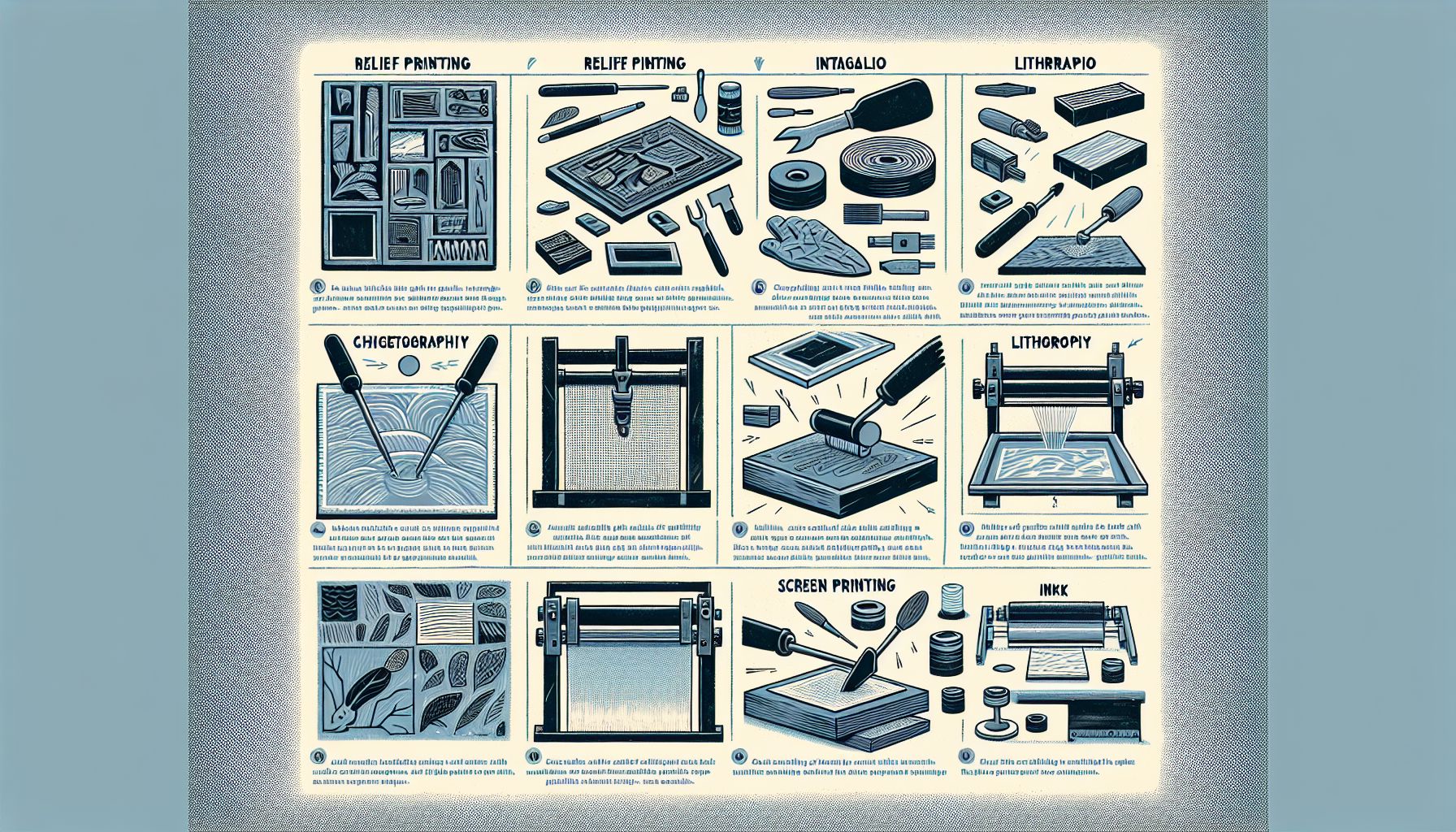

Relief printing is one of the oldest and most accessible printing techniques. It involves carving away the background of a surface, leaving raised areas that are then inked and pressed onto paper. Woodcut and linocut are common relief printing methods.

Woodcut, dating back to ancient China, involves carving an image onto a block of wood and inking the raised surface with a roller or brush. The block is then pressed onto paper, transferring the inked design. Woodcut offers bold, raw, and expressive results, making it popular among artists seeking strong visual impact.

A variation of woodcut, linocut, uses linoleum instead of wood as the carving surface. Linoleum is softer and easier to cut, allowing for finer details. Linocut prints possess a distinct graphic quality, often characterized by bold lines and contrasting colors.

2. Intaglio Printing

Intaglio printing is the opposite of relief printing. Instead of raised areas, intaglio relies on incised or etched lines and textures to hold ink. Common intaglio techniques include engraving, etching, and aquatint.

Engraving involves using sharp tools to incise lines into a metal plate, typically copper. The plate is inked and wiped, leaving ink only in the incised lines. The plate is then pressed onto paper, transferring the inked image. Engraving produces precise, highly detailed prints, often used in currency, fine art, and stationery.

Etching is a chemical process in which a metal plate is coated with an acid-resistant material, and the desired image is etched into the exposed areas using acid. The plate is inked and wiped, and the remaining ink is forced into the etched lines. When pressed onto paper, the ink transfers the image. Etching allows for a wide range of tonal values and is often favored for its ability to create atmospheric, delicate prints.

Aquatint is a variation of etching that adds tonal values to prints. Rather than using lines, aquatint relies on resin particles that create a porous surface for holding ink. By controlling the acid strength and the time the plate is submerged, artists can achieve various tonal effects, from light washes to intricate textures.

3. Planographic Printing

Planographic printing refers to the technique of printing from a flat, smooth surface. The most common planographic method is lithography. Introduced in the late 18th century, lithography relies on the principle that oil and water repel each other.

In lithography, an image is drawn or transferred onto a flat stone or metal plate using an oily substance. The plate is then dampened with water, which adheres only to the non-image areas. Ink is applied to the plate, adhering only to the oily image areas. When pressed onto paper, the ink transfers the image. Lithography enables artists to reproduce intricate detail and offers a wide range of artistic possibilities, making it popular in fine art and commercial printing.

4. Screen Printing

Screen printing, also known as serigraphy, is a versatile technique suitable for creating various prints on a wide range of materials. It involves pushing ink through a mesh screen onto the desired surface, leaving behind the intended design.

Originally used for industrial purposes, screen printing gained popularity as an artistic medium during the Pop Art movement. With its ability to produce bold, vibrant prints and accommodate various textures, screen printing offers endless creative possibilities. It has become a favored method for creating posters, apparel designs, and art prints.

5. Digital Printing

With the rise of digital technology, printing techniques have evolved to embrace the digital realm. Digital printing bypasses traditional printing plates and instead relies on digital files to transfer images onto various surfaces.

Inkjet and laser printers are the most common types of digital printing technologies. Inkjet printers spray microscopic droplets of ink onto the print surface, resulting in high-resolution prints. Laser printers, on the other hand, use electrostatic charges and powdered toner to create prints.

Digital printing offers convenience, speed, and the ability to reproduce complex designs accurately. It has transformed fields such as photography, graphic design, and advertising, enabling artists and designers to bring their visions to life with ease.

Conclusion: Embracing the Artistry of Print

Printing techniques have evolved throughout history, constantly adapting to technological advancements and artistic needs. From the expressive impact of relief printing to the delicate intricacies of intaglio and lithography, each technique brings its unique qualities and aesthetic appeal to the world of visual communication. Screen printing and digital printing offer versatility and convenience, ensuring that the art of print continues to thrive in the modern era.

As we have journeyed through the diverse world of printing techniques, we have observed their significance in shaping our visual landscape. Whether you are an artist exploring new creative avenues or a design enthusiast eager to understand the artistic process, diving into the art of print is an exploration that rewards with infinite possibilities. So, let us celebrate the heritage and embrace the innovations of printing techniques that continue to captivate our senses and breathe life into the visuals that surround us.