In this digital age, catalogs remain a valuable tool for businesses to showcase their products and services. They provide customers with a physical way to browse through your offerings and give your brand a tangible presence in their homes. If you’re thinking about printing a catalog for your business, you’ve come to the right place. In this comprehensive guide to catalog printing, we will provide you with everything you need to know to create a practical and beautiful catalog that stands out.

5 steps to Catalog Printing

1. SET YOUR GOALS

Before you start designing your catalog, it’s essential to define your goals. What do you want to achieve with your catalog? Are you looking to increase sales, promote new products, or educate your customers about your brand? Once you’ve defined your goals, you can use them to guide your design decisions and create a catalog that’s tailored to your audience.

2. CHOOSE YOUR FORMAT

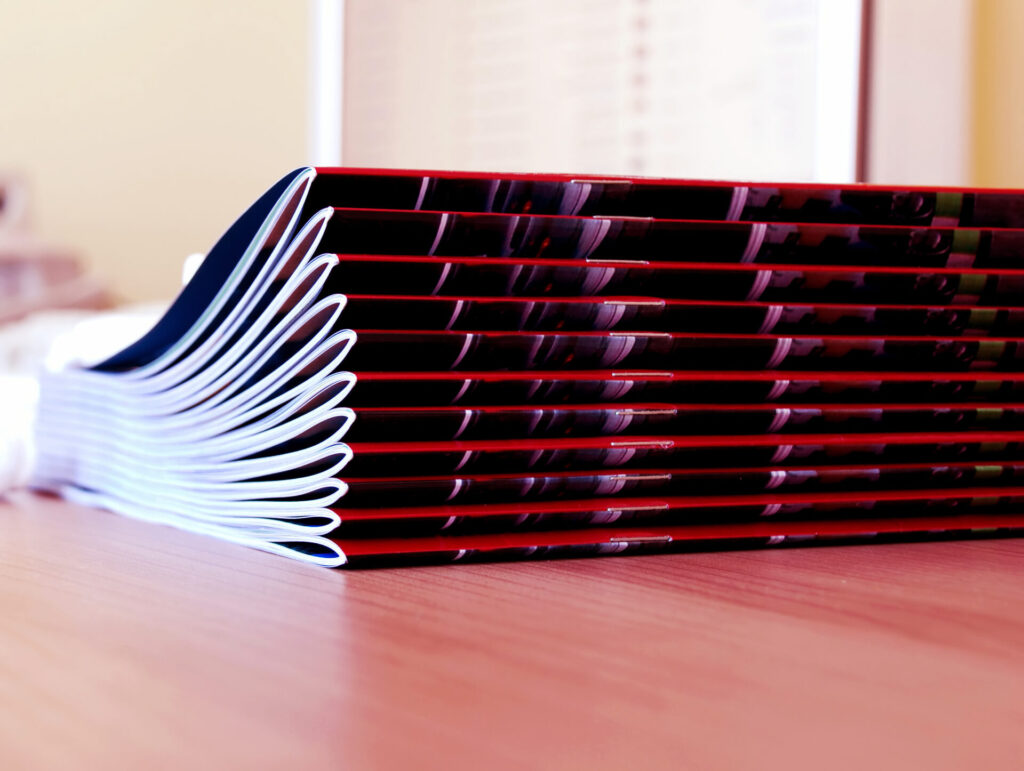

There are many different catalog formats to choose from, including saddle-stitch, perfect-bound, and wire-o. Each format has its advantages and disadvantages, so it’s important to choose one that’s right for your business. Consider your budget, the number of pages you need, and the type of products you’re showcasing when selecting your format.

3. DESIGN YOUR LAYOUT

Your catalog’s layout is crucial to its success. It’s essential to create a design that’s easy to navigate and visually appealing. Use high-quality images and graphics, and make sure your text is easy to read. Take the time to plan your layout before you start designing to ensure a cohesive and professional look.

4. WRITE YOUR COPY

Your copy is just as important as your design. It’s essential to write copy that’s engaging, informative, and persuasive. Use clear and concise language, and focus on the benefits of your products rather than just their features. Don’t forget to include your contact information and a call-to-action to encourage your readers to take action.

5. PRINT AND BIND

Once you’ve designed and written your catalog, it’s time to print and bind it. Choose a high-quality printer that specializes in catalog printing, and make sure to proofread your catalog before sending it to print. Consider adding special finishes like UV coating or embossing to make your catalog stand out even more.

Printing a catalog is an excellent way to showcase your products and services and give your brand a tangible presence in your customers’ homes. By following these five steps, you can create a practical and beautiful catalog that stands out and helps you achieve your business goals. Good luck!

The first step in catalog printing is planning and designing your catalog. You need to figure out what products or services you want to showcase, how many pages you want your catalog to be, and what kind of layout you want to use. Keep in mind, your catalog should be visually appealing and easy to navigate. Hire a professional designer to create a cohesive and branded design for your record. They should create a record that is legible, with well-organized content, and high-quality images. You need to consider what colors, fonts and images you want to use in your catalog to capture your brand’s essence.

Printing options:

Designing a catalog is a meticulous process that requires attention to detail and a keen eye for design. Once you’ve finished designing your catalog, the next step is to carefully select a printing company to partner with. This step is crucial in ensuring that your catalog meets your expectations and impresses your target audience. In this article, we’ll discuss the different printing options available, such as digital and offset printing, and provide tips on how to choose the right printing company for your catalog.

Understanding Digital Printing

Digital printing is a more cost-effective option for small-scale printing, as it entails printing directly from digital files, eliminating the need for printing plates. This process also allows for quick turnaround times and is suitable for printing on demand. Digital printing is perfect for catalogs with a short print run, personalized catalogs, or catalogs that need frequent updates.

Understanding Offset Printing

Offset printing is the more efficient choice when printing many catalogs. It involves transferring the inked image from a printing plate to a rubber blanket, which is then pressed onto the paper, resulting in high-quality and consistent prints. Offset printing produces vibrant colors and sharp images, making it ideal for catalogs with intricate designs or photographs. However, this process requires the creation of printing plates, which adds to the cost and time required for printing.

Choosing the Right Printing Company

When choosing a printing company, it’s essential to consider the quality of materials and ink used, as well as their reputation for delivering exceptional printing quality. A reputable printing company should offer a range of paper choices, such as glossy or matte finishes, and use high-quality ink that ensures vibrant colors and sharp images. Additionally, the printing company should provide excellent customer service and be able to accommodate your specific needs and requirements.

In conclusion, selecting the right printing company is crucial in ensuring that your catalog meets your expectations and impresses your target audience. Understanding the different printing options available, such as digital and offset printing, and choosing a reputable printing company that delivers exceptional printing quality will ensure that your catalog stands out from the competition.

Paper and finishing options:

When it comes to creating an effective and visually appealing catalog, it’s essential to choose the right paper type and finishing. There are numerous paper options to consider, each with its unique characteristics. Gloss paper, for example, is an excellent choice for showcasing product images as it provides a vibrant and vivid finish. On the other hand, matte paper is ideal for text-heavy catalogs as it is easy to read and free from glare. Additionally, uncoated or textured paper can add a tactile element to your record, making it stand out.

In terms of finishing, you have several options, depending on the size and style of your catalog. For smaller logs, saddle stitch binding is a great choice, as it allows the pages to lay flat and makes it easy for readers to flip through the pages. For more extensive catalogs, however, perfect binding or wire-o binding may be a better option, as they offer a more professional finish and can withstand regular use. Ultimately, the key is to select a paper type and finishing that complements your catalog’s overall design and helps convey your brand’s message effectively.

Distribution:

Once the catalog has been printed successfully, it is imperative to devise a distribution plan to ensure maximum reach and visibility. There are several approaches you can take, including in-store distribution, mailing to potential customers, and inserting the catalog in local newspapers and magazines. However, it is also advisable to provide a digital version of the catalog, which can be accessed online by customers. This will not only make the catalog more accessible but also broaden your audience reach.

To ensure that the catalog gets the attention it deserves, promoting it across all your website and social media platforms is vital. This will help boost visibility and increase the likelihood of customers coming across it. By taking these steps, you can maximize the impact of your catalog and increase the chances of it being viewed by your target audience.

Measuring success:

Assessing the effectiveness of your catalog is an integral part of calculating the return on investment for the resources invested in its development and distribution. It is essential to monitor and analyze the leads and conversions generated by your catalog to evaluate its success. One practical approach to achieve this is by utilizing distinct catalog codes or URLs to track the performance of your catalog. Incorporating these tracking methods can provide you with valuable insights on the efficiency of your catalog, enabling you to make necessary modifications to increase its success rate.

Analyzing the data

By analyzing the data collected from your tracking endeavors, you can identify the areas that need improvement. It is essential to make the necessary modifications to your catalog to enhance its effectiveness continually. If the results of your tracking endeavors display a positive impact, it is advisable to proceed with producing and distributing your catalog while implementing any essential improvements to guarantee sustained triumph.

In conclusion, monitoring and analyzing the performance of your catalog is crucial to maximize its effectiveness and achieve a high return on investment. By incorporating tracking methods and making necessary modifications based on the data collected, you can ensure sustained success and growth for your business.

Conclusion:

Catalog printing may seem daunting, but with the right strategy and professional help, it can be a lucrative investment for your business. Remembering the steps above helps ensure your enterprise creates a profitable and gorgeous catalog. Work with a reputable printing company, invest in brochure design, choose the right paper to finish, distribute widely, and measure how the chronicles impact your business. Remember small things such as proofreading, good images, and fonts. Printing a record is worth it in the long run, as it helps promote brand identity and attract new customers. Read more at Alpaca Consulting.