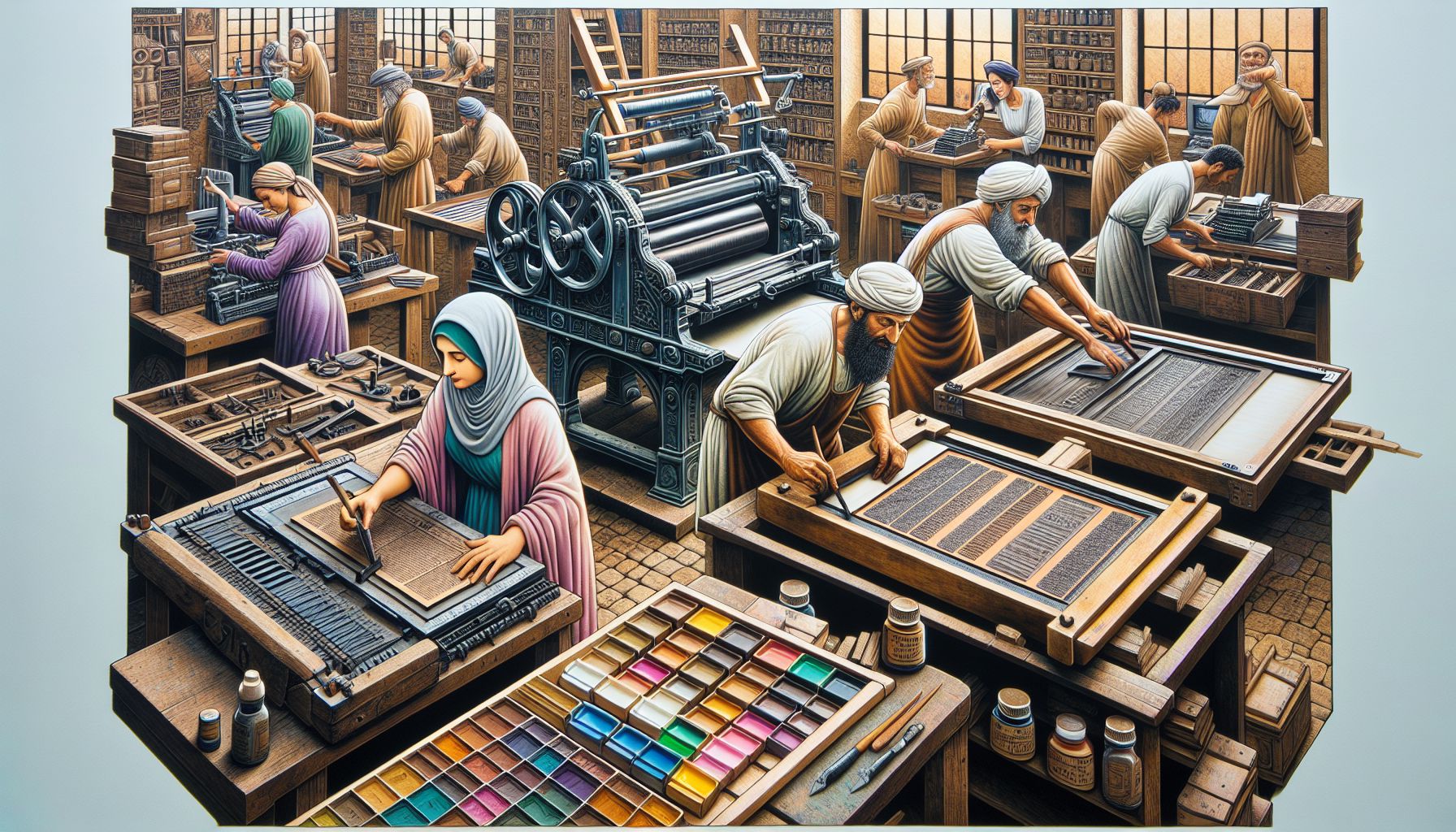

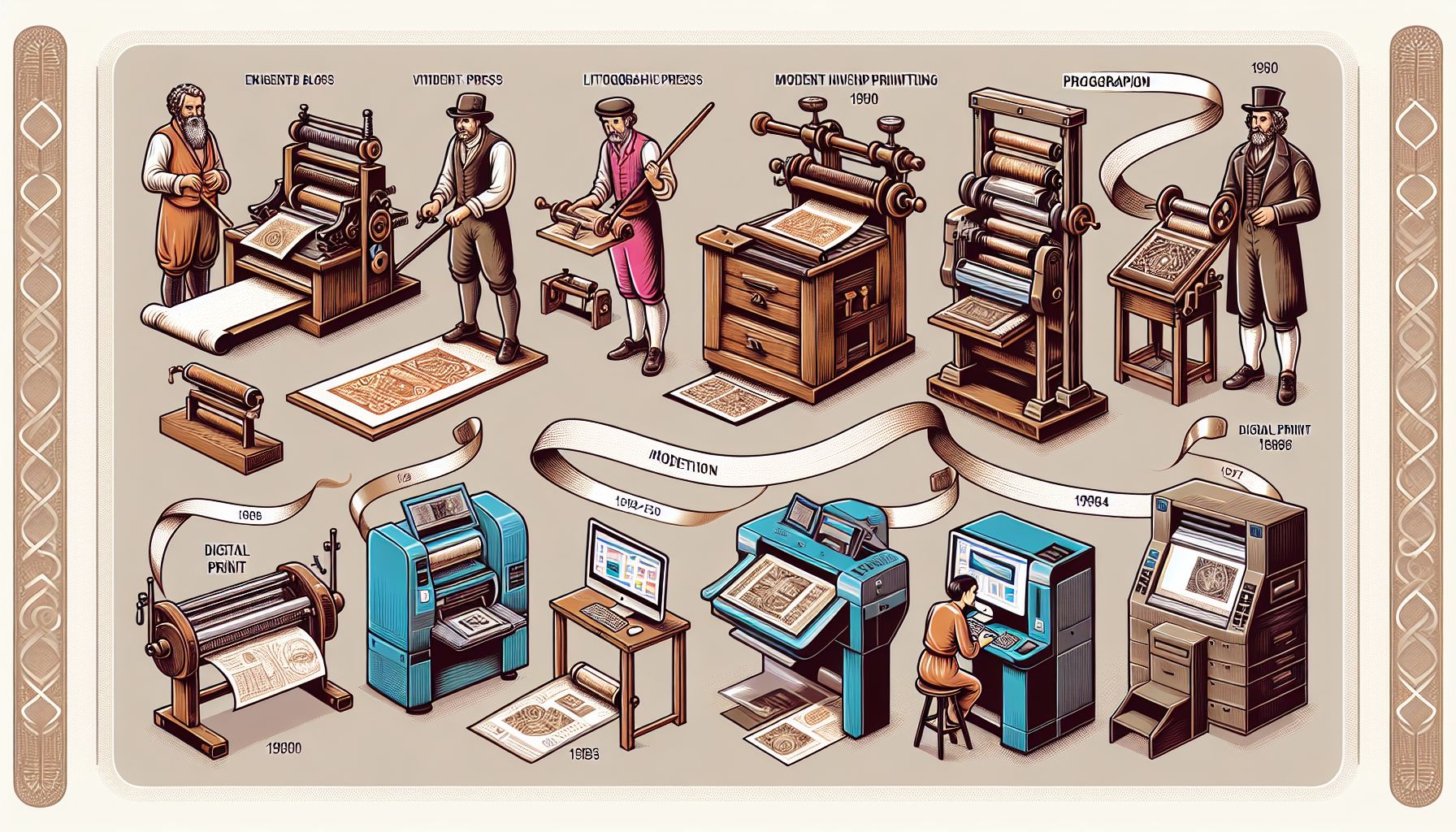

Printing has been an essential part of human communication for centuries. From the Gutenberg printing press to modern digital technologies, the art of printing has evolved drastically over time. In today’s digital age, there are various printing techniques that cater to different needs and preferences. In this article, we will explore some of the most popular printing techniques, including offset printing, digital printing, and screen printing.

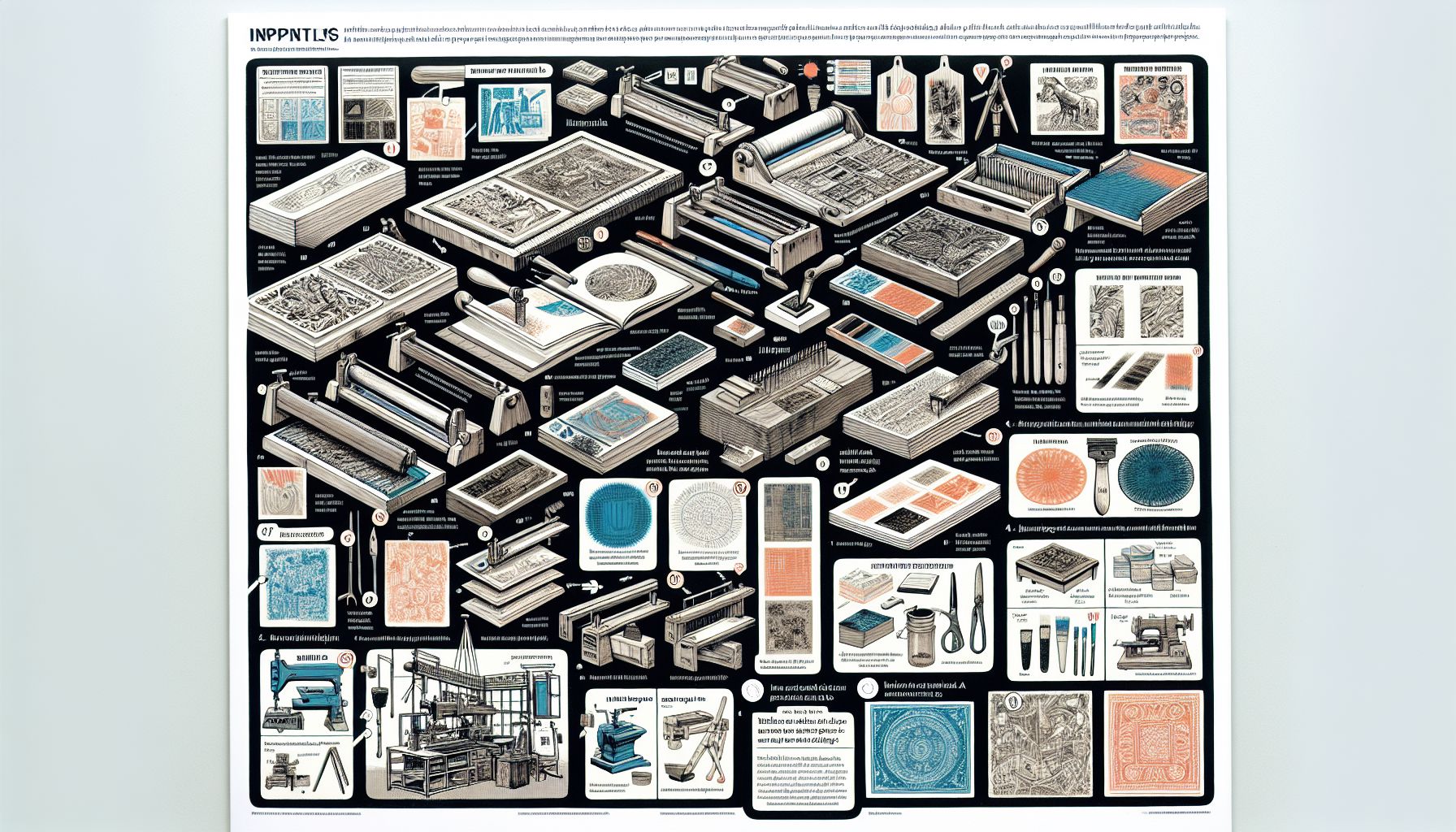

Offset Printing

Offset printing is one of the most widely used printing techniques in the commercial printing industry. This method involves transferring an inked image from a plate to a rubber blanket, then onto the printing surface. Offset printing is known for its high-quality results, sharp details, and vibrant colors. It is commonly used for printing magazines, brochures, and packaging materials.

One of the main advantages of offset printing is its cost-effectiveness for large quantities. The setup costs for offset printing can be high, but the per-unit cost decreases as the quantity increases. This makes offset printing an ideal choice for businesses looking to produce a large volume of printed materials.

Digital Printing

Digital printing has revolutionized the printing industry with its speed, flexibility, and cost-effectiveness. This method involves directly printing an image from a digital file onto various substrates, such as paper, canvas, or vinyl. Digital printing is perfect for short print runs, quick turnaround times, and customization.

One of the key advantages of digital printing is its ability to produce variable data printing, where each print piece can be customized with different text or images. This makes digital printing ideal for personalized marketing materials, such as direct mail campaigns and promotional items.

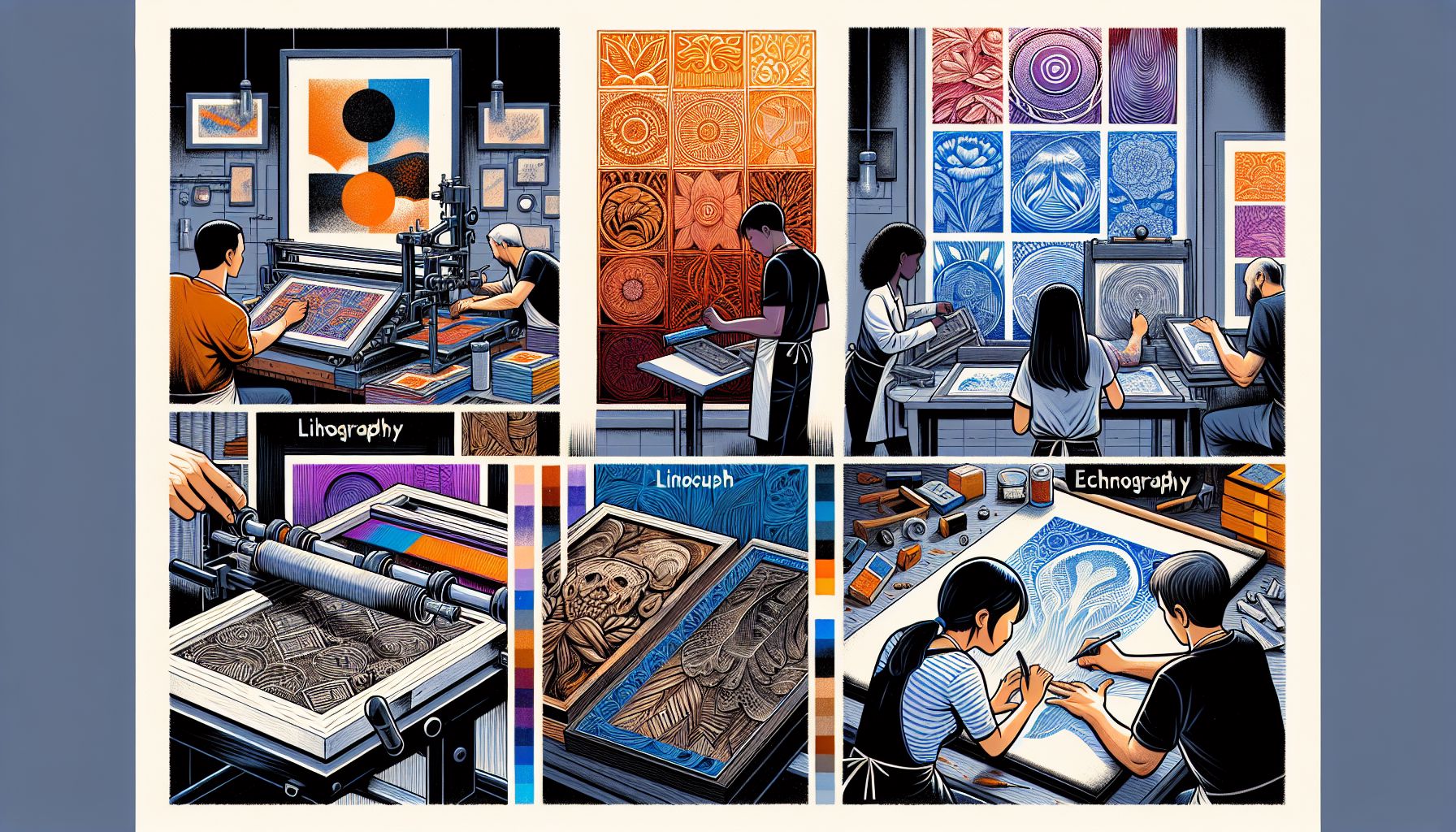

Screen Printing

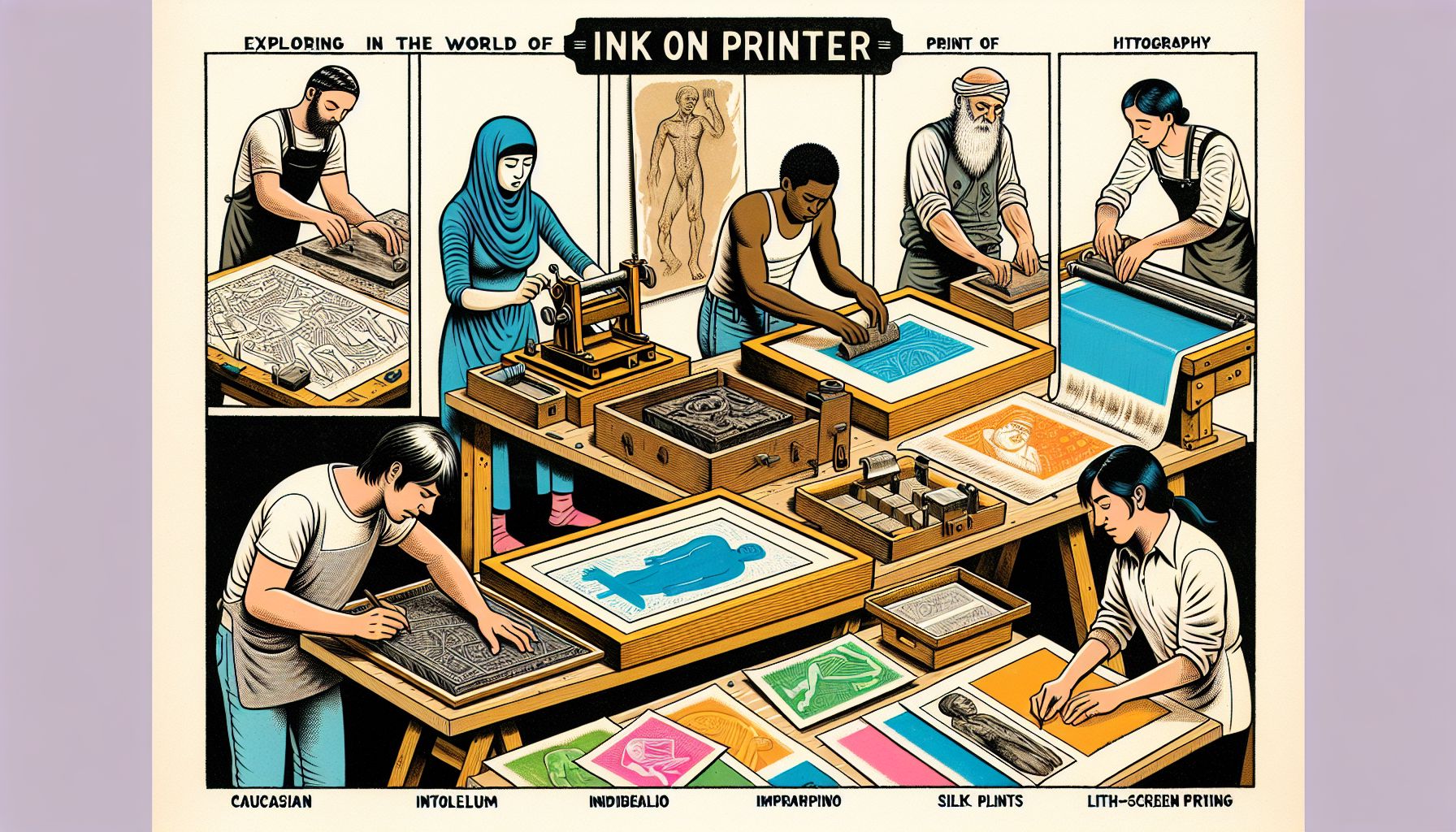

Screen printing is a versatile printing technique that uses a stencil (or screen) to transfer ink onto a printing surface. This method is commonly used for printing on apparel, such as t-shirts, hoodies, and tote bags. Screen printing is known for its vibrant colors, durability, and ability to print on various materials.

One of the main advantages of screen printing is its ability to produce bold and opaque prints on dark or colored fabrics. This makes screen printing a popular choice for creating custom apparel, promotional items, and merchandise.

Flexography

Flexography is a modern printing technique commonly used for packaging materials, labels, and newspapers. This method involves transferring ink from a flexible printing plate onto a substrate, such as paper, plastic, or cardboard. Flexography is known for its fast printing speeds, high-quality results, and ability to print on a variety of substrates.

One of the main advantages of flexography is its ability to produce consistent and precise prints, even on rough or uneven surfaces. This makes flexography ideal for printing on packaging materials with intricate designs or specific color requirements.

Conclusion

Printing techniques have come a long way since the invention of the Gutenberg printing press. From traditional offset printing to modern digital technologies, there are various methods available to meet the diverse needs of today’s printing industry. Whether you’re looking to print a magazine, a t-shirt, or a packaging label, there is a printing technique that’s perfect for the job. Next time you need to print something, consider exploring the world of printing techniques and choose the method that best suits your needs.